Mechanics of Advanced Materials Laboratory

Mechanics of Advanced Materials Laboratory, located at three different buildings across the campus–North Lab, ECSW, and NSERL, is home to several research and laboratory facilities that are available to the researchers across UT Dallas.

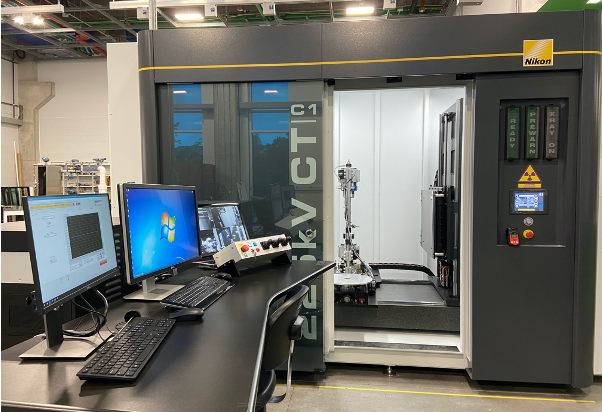

In-situ 225 kV X-ray CT System

The X-ray CT system has an integrated loading frame. It is capable of applying simultaneous axial and torsional loads up to 45 kN in axial load and up to 300 N·m in torque. It has a large workspace to allow scanning a wide range of parts. The high energy allows the X-ray to penetrate through 2-inch metals and other materials.

The equipment is available for both academic and industrial users as a paid service. If you have an interest to obtain a quote, please provide and describe your testing need to Runyu: runyu.zhang2@utdallas.edu

Advanced Materials Laboratory

This facility includes walking and custom fume hood settings and production facilities mainly for the material synthesis and fabrication. Several types of temperature controller ovens containing vacuum oven (Fisher Scientific™ Isotemp™ Model 281A), mechanical convection oven (Binder FD 53) and air safe oven (Blue M Friction-Aire) are available for the possible required heat treatments. For the surface roughness sensitive experiments such as indentation and metallographic experiments, we have a semi-automatic polishing machine (FEMTO 1100) with variable polishing speed up to 200 rpm. In addition, specifically for the drying of aerogel or biological samples, a fully automated critical point dryer (Leica EM CPD300) is available to preserve the structure of the specimen which could otherwise be damaged or collapsed due to the surface tension of the vaporizing inner liquid phase.

Impact Test Laboratory

This facility contains various experimental setups to measure the static and dynamic mechanical properties of materials at different environmental and loading conditions. Different types of experiments can be carried out based on the nature of materials. These facilities can be categorized into different groups as follows.

1 – Quasi-Static and Fatigue Testing

For low strain rate (less than 1 1/s) experiments, a fully electric controlled test instrument (ElectroPuls™ E10000 Linear-Torsion) with a wide range of load cells (10 N, 50 N, 500 N, 1 KN, 10 KN, 50 KN) is available to cover the tensile, compressive, torsion and bending properties of various materials and components at different configurations. Mechanical properties of thin films and membranes can be done with a custom built apparatus to carry out bulging test with real-time pressure transducer measurements.

2 – High Strain-rate and Dynamic Testing

Stress-strain behavior of time-dependent materials is highly dependent on the strain-rate. Therefore it is required to study such materials at strain-rates higher than the quasi-static range. The impact lab is home to several types of required setups including Hopkinson Bars and Shock Tubes that can provide the material properties at high strain-rates. Of course, High-Speed Photography is an inevitable part of these experiments. The details of the setups and facilities are listed below.

Hopkinson Bars

The Hopkinson bar is an apparatus for testing the dynamic stress-strain response of materials. Two different lengths of Hopkinson Bar are available in this lab.

(A) Long split Hopkinson Pressure bar (80 ft in total, 29 ft incident ¾” stainless solid bar, 23 ft long gas gun barrel, 29 ft long transmission bar)

(B) Miniature split Hopkinson tension bar (24 ft in total, 12 ft long 7075-T6 ¼” solid incident bar, 8 ft long ¼” hollow transmission bar)

The equipment is available for both academic and industrial users as a paid service. If you have an interest to obtain a quote, please provide and describe your testing need to Runyu: runyu.zhang2@utdallas.edu

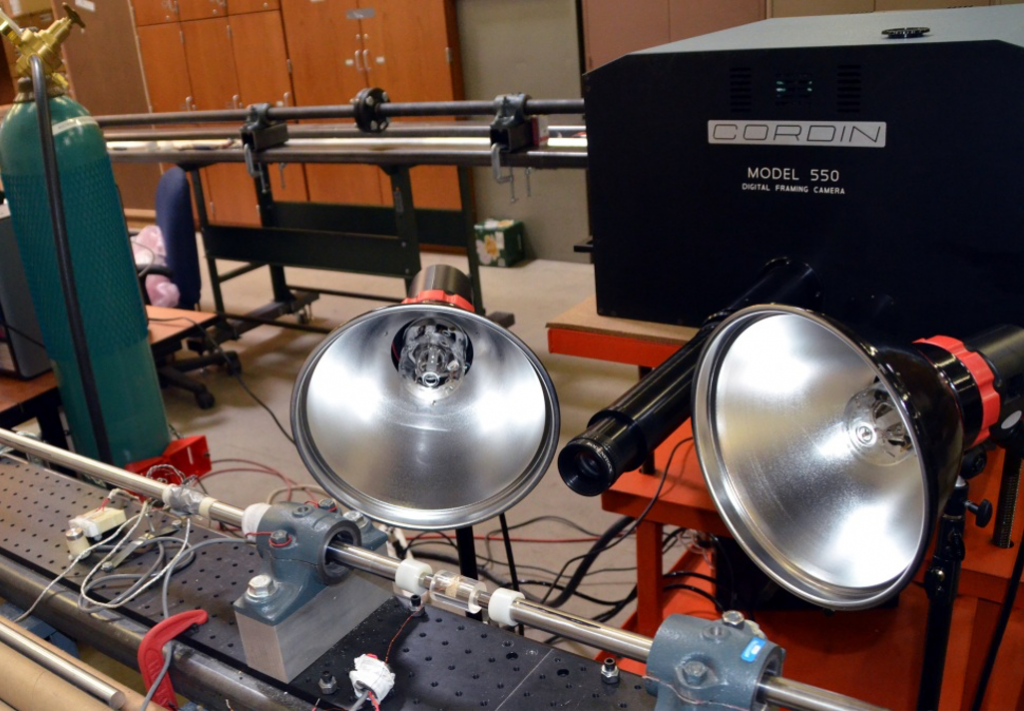

High-Speed Photography

High-Speed Photography is the technique of taking pictures at a very high number of frames per second.

(A) Cordin 550-62 High-speed camera system (up to 4 M fps, 1000×1000 pixel color CCD)

(B) SA6 high-speed camera (1080P at 2000fps, 512×256 P at 10.8k fps)

The equipment is available for both academic and industrial users as a paid service. If you have an interest to obtain a quote, please provide and describe your testing need to Runyu: runyu.zhang2@utdallas.edu

Vibration and Drop Tower

This drop test setup is able to provide impact loading up to 2 kg. With the laser doppler vibrometer & vibration shaker (up to 13,000 Hz), it can measure the accurate acceleration during the impact.

Shock Tubes

The shock tube is an instrument to be used to simulate an explosion and its effects on a material on a smaller scale. Again we have two different size shock tubes in the lab.

(A) Light-duty shock tubes: 7 ft long vertical in total, 0.75” ID, 300 psi

(B) High-duty shock tubes: 40 ft long horizontal in total, 1.5” ID, 300psi)

3 – Full-field, Non-contact Displacement, and Strain Measurements (Digital Image Correlation)

Digital Image Correlation (DIC) is a non-contact technique to measure the deformation, vibration and strain fields on almost any type of material. A custom-built verified DIC software (SpeckleTrack) is available that can be utilized for different 2D and 3D experimental applications.

Nanoindentation Laboratory

Over the last decade, the indentation technique has been developed for the purpose of probing the mechanical properties of very small volumes of material. This technique is ideal for mechanical characterization of thin films, coatings, and surface layers. We have a Nano Indenter (Agilent G200) with a maximum indentation depth of 500 μm with 0.2 nm resolution and a maximum load of 500 mN with 50 nN resolution. Due to the high sensitivity of this type of experiment to the temperature and vibration, this facility is located in the basement of the Natural Science and Engineering Research Laboratory at UT Dallas.