The Group has continued its efforts to “democratize” drug delivery. We had previously published a method on 3D printing micro-needle delivery systems, which graced the cover of PC Magazine and was covered by the popular media.

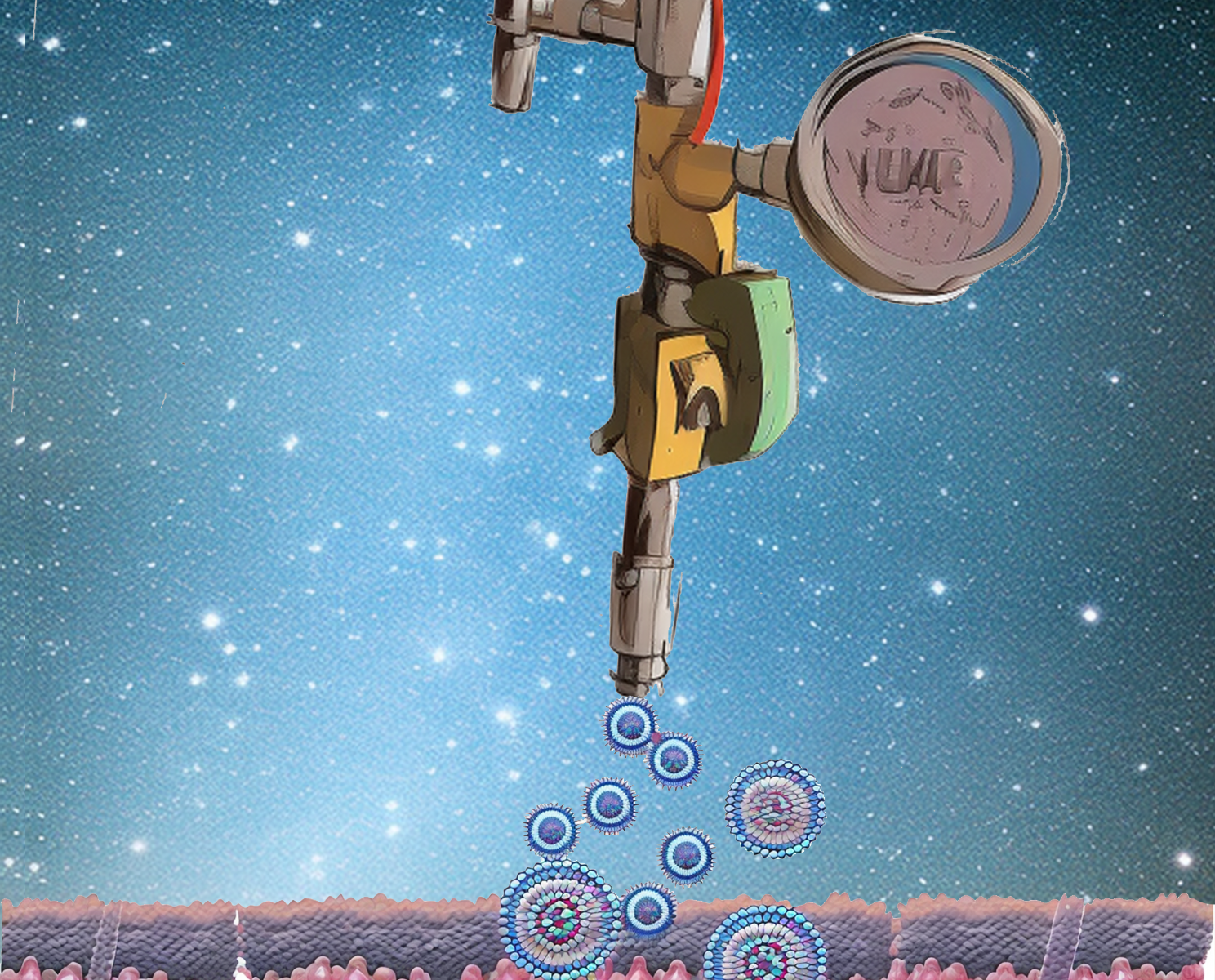

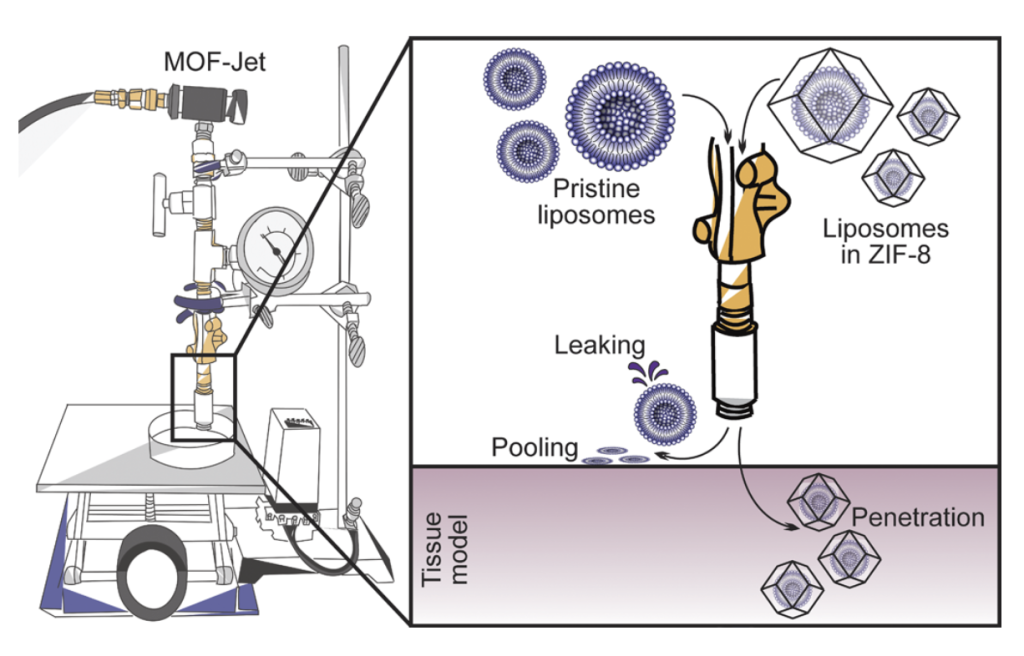

Well, we got bored with microneedles and went full Texas and built a gun to just shoot drugs right into people. Yes, Jet-injectors are/were a thing, but they have well-documented issues related to using water as the carrier vehicle. Vaccines and medicines dissolved in water used to be shot into people’s skin; however, the water would splash back out of the injection site and onto the jet injector, spreading disease. Having found a way to powderize and indefinitely stabilize anything—from viruses to DNA adjuvants, to whole cell bacteria, to full liposomes— inside a metal-organic framework called ZIF-8, we figured we could just shoot our drugs as a powder using high-pressure gas and… not only does it work, you can control the pharmacokinetics of the material by using carbon dioxide as the carrier gas.

Yalini and coworkers published the first article in Chemical Science that specifically looks at using carbon dioxide to dissolve the ZIF quickly once it gets into tissue. As we all know, carbon dioxide in water becomes carbonic acid, and acids very rapidly dissolve the ZIF shell. Consequently, when one shoots a ZIF-coated material into tissue using carbon dioxide, the material is delivered into the skin and is bioavailable almost immediately. If one uses air, which does not react with water and does not form any acids, the material enters the skin still in the ZIF coating. That coating takes a few days to dissolve, slowly becoming bioavailable over several days. This has become pretty popular with no shortage of write-ups in the popular media. This is all explained pretty well in a press release by the American Chemical Society (ACS). Yalini gave a talk at the ACS National Meeting in Indianapolis, and by chance, the ACS picked her abstract for a press release. They even made a video that explains it (below):

We even went a step further and showed how the mechanical stability of the ZIF promoted the shooting of delicate liposomes into tissues. Sneha’s PNAS article shows that the enhanced mechanical strength offered by a shell of only ~100 nanometers thin is sufficient to let liposomes be shot into the skin. Liposomes, like most lipid nanoparticles, are notoriously fragile and do not survive the strong forces of being shot onto a surface. Liposomes can resist forces up between 100pN to 1nN, which is very small; however, inside a ZIF Shell, about 100 nM thick, this increases to ~3 μN, representing an enhancement of many orders of magnitude.