The Neural Interfaces Lab (NIL) works on the design and testing of devices for neural stimulation and recording. We establish microfabrication processes for building improved neural devices, investigate thin film materials for neuroscience applications, evaluate bench-top electrochemical behavior of electrodes, and test in vivo performance and stability of microelectrode arrays (MEAs). We evaluate devices for neural engineering applications by combining microscopy, analysis of materials, electrochemical evaluations, accelerated testing, failure analysis, and animal studies.

Materials Research and Device Fabrication

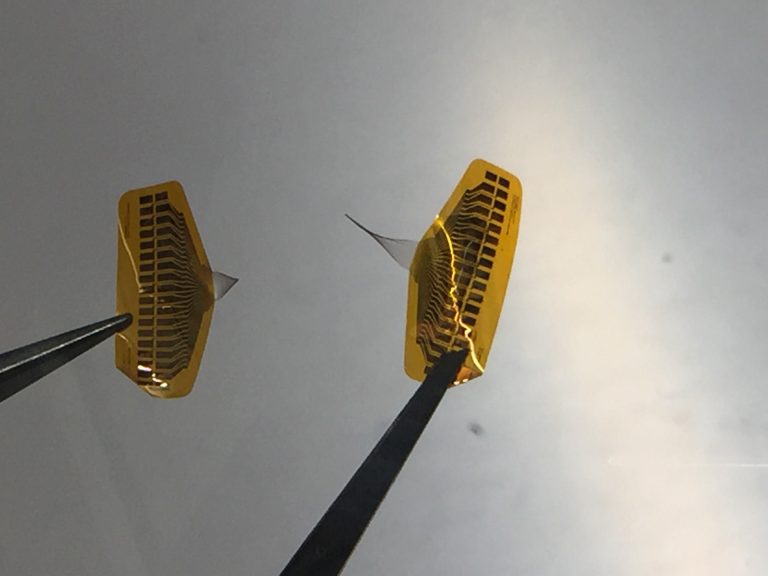

- Developing amorphous silicon carbide (a-SiC) based ultra-thin microelectrode arrays (UMEAs) for intracortical neural recording and stimulation.

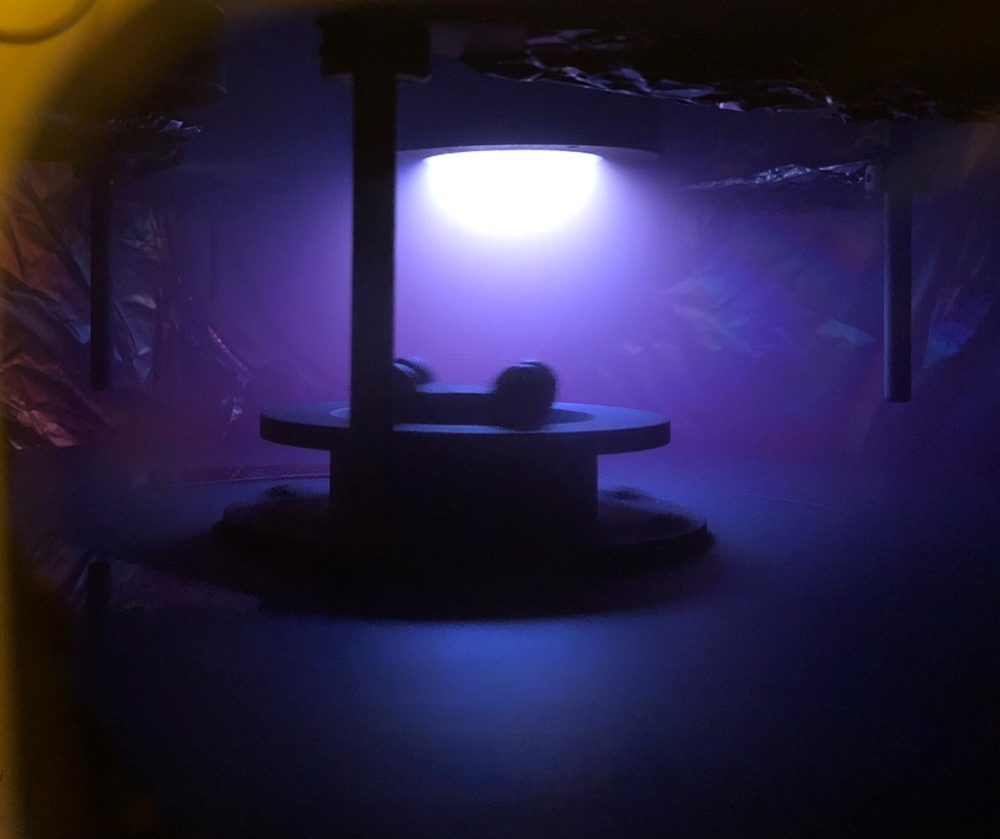

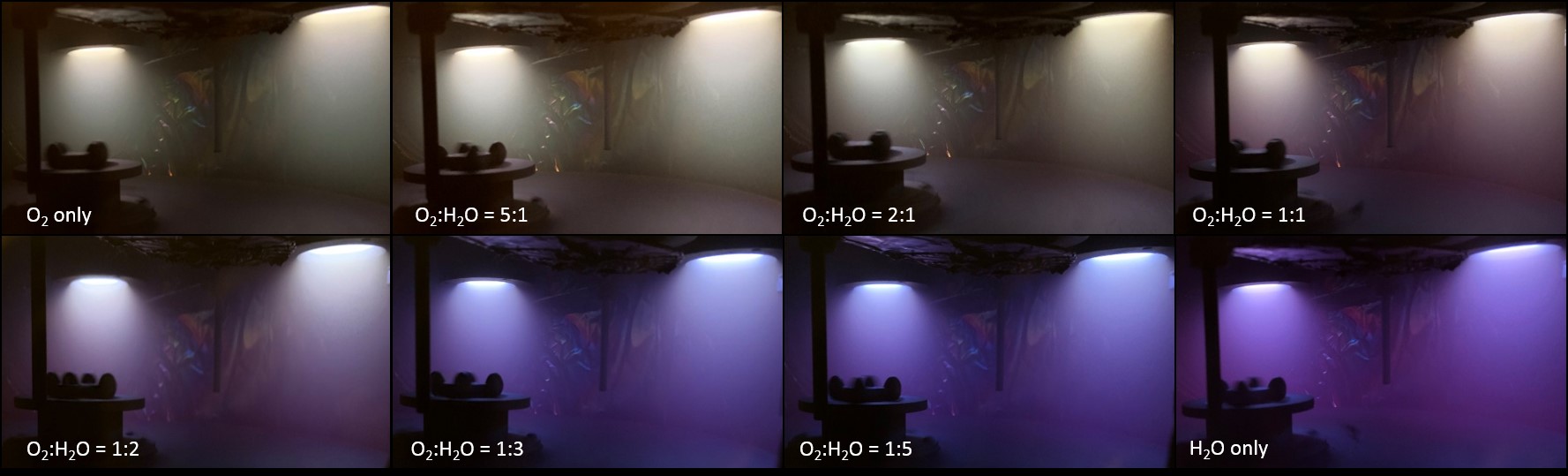

- Developing stable sputtered iridium oxide film (SIROF) and ruthenium oxide film (RuOx) using reactive DC magnetron sputtering for chronic neural stimulation and recording.

- Evaluating chronic stability of Parylene-C devices with a-SiC encapsulation.

- Understanding electrochemical mechanisms that cause changes in electrode charge injection capability in vitro vs. in vivo.

- Developing durable SIROF micro-supercapacitors for energy storage in implantable bioelectronics.

- Testing a-SiC encapsulation through leakage current measurement and understanding breakdown electrical breakdown phenomena.

Neural Device Performance Testing

- Evaluating an intracortical vision prosthesis utilizing a wireless floating microelectrode array (WFMA).

- Evaluating functional changes in the rat caused by chronic implantation of a WFMA in sciatic nerve.

- Establishing methods for electrochemical characterization of the in vivo performance of electrodes.

- Evaluating chronic stability of SIROF-coated Utah arrays both in vitro and in vivo.

- Evaluating long-term reliability of intracortical MEAs in vivo.